In cattle farming, a sufficient supply of water of the best possible quality, as well as a supply of feed, is of essential importance for the economic success of a barn. A cow’s body consists of up to 70% water. The water content of milk is as high as 87%. Water is of central importance for the health of cows. It fulfils vital functions such as nutrient transport, digestive processes and thermoregulation.[1]

Cows have a particularly high water requirement. In summer, cows consume more than 130 litres of water per animal per day. With higher milk yields and higher feed requirements, the water requirement is even higher. As water intake decreases, the animals’ intake of dry feed matter also decreases.[2] Water can therefore be described as the animals’ most important feed, and it should always be available in sufficient quantities and of good quality.

Water is a crucial nutrient for pigs. Its role is vital because the loss of 10% of body water can cause the death of the animal.[1] Water plays a major role in maintaining body temperature, acid-base balance, controlling satiety and animal behavior.[1]

Good water intake also promotes the intake and utilization of dry feed matter and thus the performance of the animals. Therefore, water is one of the most important feedstuffs that should always be available in sufficient quantity and of good quality, as it is essential for the economic success of a stable facility.

Water is a crucial nutrient for poultry. Its role is vital because the loss of 10% of body water can cause the death of the animal.[1]

Water plays a major role in maintaining body temperature, acid-base balance, controlling satiety and animal behavior.[1] Good water intake also promotes the intake and utilization of dry feed matter and thus the performance of the animals. Therefore, water is one of the most important feedstuffs that should always be available in sufficient quantity and good quality, as it is essential for the economic success of a livestock facility.

Water – the most important feed.

Company water supplies are usually made from groundwater, which is usually available close to the farm and is pumped from deeper soil layers, the aquifers, via boreholes.

Groundwater is recharged through rainwater and, to a small extent, from surface water. As it seeps through the upper soil layers, the water is both filtered and changed in many ways by dissolving and microbiological processes. The absorption of valuable minerals and trace elements alone improves the quality of the water in terms of health aspects for humans and animals.

Having your own water is worth it

Cattle herds have increased significantly on average in recent years. Due to the significantly higher water demand, the supply of one’s own water is becoming increasingly important. Own water supplies with treatment to drinking water quality result in significant cost savings. From an economic point of view, they are now a must.

Public water

The price of public water varies, but is mostly in the range of around €1.00/m³.

Private water

In contrast, with private water supplies it is quite possible to permanently reduce the price to around €0.08/m³ by selecting advantageous components for equally good water quality.

[2]ava1.de/pdf/artikel/rinder/2004_04_mahlkow-nerge.pdf; Dr. Katrin Mahlkow-Nerge, Ohne Wasser keine Milch, Nutztierpraxis aktuell, Ausgabe 10, Sept. 2004

Difficulties caused by groundwater use

During the complex and varied processes of groundwater recharge, the oxygen originally contained in the rainwater is consumed. As a result, the metals iron and manganese are dissolved and a certain amount of ammonium is formed.

Iron and manganese are trace elements for cattle that the body needs, but which are excreted again if too much is consumed. However, the need is usually more than covered by the feed. On the other hand, increased iron and manganese levels lead to significant problems in animal husbandry.

Sensory water quality

A major problem in cattle farming is the deterioration of the taste as the iron content increases. Cattle check the water quality with their sense of smell and especially carefully with their sense of taste.

The unpleasant taste leads to lower water intake by the animals and thus to reduced feed intake and utilization.[1]

The consequence for cows is lower milk yield. The Schleswig-Holstein Chamber of Agriculture states that with a reduced water intake for every 1.44 l of water, milk yield drops by 1 kg.[2]

In bulls and calves, reduced water intake leads to poorer fattening performance. In addition, the saleable quality of the veal in fattening calves decreases when they ingest water containing iron. In general, if the animals do not drink enough water, their health stability is impaired.[2]

Chemical water quality

Soaking water quality

Drinking water quality

Iron and manganese deposits (ochre deposits)

Iron and manganese also cause significant problems in the water supply systems themselves, through the ochre formation of wells and pumps, as well as deposits in pipes and drinking troughs.[1] Eliminating the effects of iron in the system is usually associated with considerable time and expense. The ochre formation of wells often leads to a significant reduction in their performance and service life, or the need for regeneration or reconstruction.

Using the FERMANOX® process effectively prevents ochre formation of the entire water supply from the outset. When using FERMANOX® systems, no water containing iron and manganese flows through wells, pumps and water pipes, as the water is treated before it is pumped.

Iron deposits – calcified impeller in a submersible pump

[1] http://www.lksh.de/fileadmin/user_upload/Presse/Archiv_2011/BB_4211_22.10.2011/42-44_Fuebbeker.pdf ; Alfons Fübecker, Landwirtschaftskammer Niedersachsen, Wasserenteisenung dringend notwendig, 22.10.2011

[2] http://www.lksh.de/landwirtschaft/tier/rinder/ ; Homepage der Landwirtschaftskammer Schleswig-Holstein.

[3] http://www.landwirtschaftskammer.de/lufa/download/fachinfo/wasser/beurteilungswerte-traenkwasser.pdf ; Beurteilungswerte für Tränkwasser, Landwirtschaftskammer Münster

The solution: Underground iron and manganese removal (UEE) with FERMANOX water treatment plants

The underground iron and manganese removal of groundwater (UEE) with FERMANOX® activates a natural treatment process in the aquifer before extraction. With little effort, iron and manganese concentrations at drinking water level can be generated there. This effectively prevents all ochre deposits in wells, pumps and pipes. At the same time, the process is particularly sustainable because

- no filter material is required,

- no waste water or waste is produced,

- energy requirements are particularly low and

- the service life of the boreholes is increased.

FERMANOX® plant for underground iron and manganese removal

The process: Underground iron and manganese removal with FERMANOX

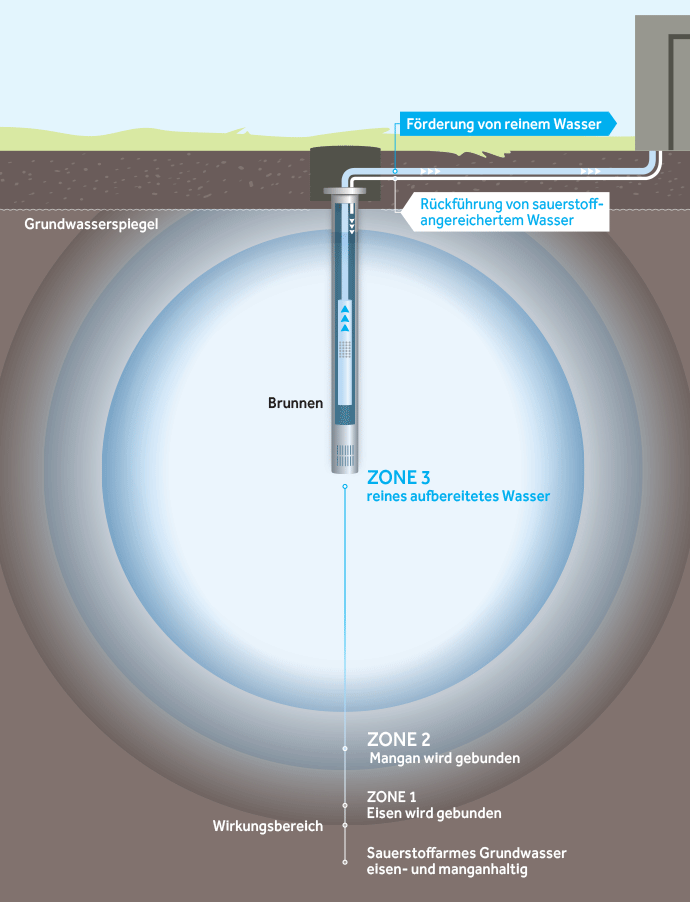

Oxidation areas in the aquifer when using a UWE

The basic idea behind underground deferrification and demanganization is the introduction of water enriched with atmospheric oxygen into the aquifer. Even small amounts of oxygen activate an effective water treatment process there, because a reaction space with an increased redox potential is created around the well.

The substances that were dissolved in the aquifer due to reduced conditions are returned to the solid state by oxidation and are then permanently fixed again in the same aquifer at another location. This achieves efficient deferrification and demanganization of the groundwater and also nitrification of ammonium, a reduction in easily oxidizable organic substances and a reduction in arsenic.

Continuous underground water treatment is based on the operation of at least two wells that work alternately as extraction or infiltration wells. The size of the reaction space around each well is determined by the amount of infiltration and the proportion of active pore volume in the aquifer. It requires an individual design for each well, which is based primarily on the raw water quality and the required treatment capacity.

Historie

Die unterirdische Enteisenung und Entmanganung von Grundwasser wird seit den 70er Jahren im großtechnischen Maßstab, seit den 80er Jahren auch in einer Vielzahl von kleinen und mittleren Anlagen zur Trink- und Brauchwasseraufbereitung vor allem in Deutschland, in den Niederlanden und in Skandinavien in verschiedenen Konzeptionen eingesetzt. Seit 1984 stellt die Winkelnkemper GmbH FERMANOX®-Wasseraufbereitungsanlagen her und ist mit inzwischen über 10.000 installierten Kompaktanlagen Marktführer auf dem Gebiet der unterirdischen Enteisenung und Entmanganung.

The basic requirement for the use of FERMANOX® systems for underground iron and manganese removal is vertical or horizontal filter wells in loose rock (sand or gravel), because the actual processing requires, above all, the large surface area of a porous aquifer. The usual technical rules apply to the well construction (especially DVGW W 113, W 123 and DIN 4924). In addition, it is particularly important to ensure that no vertical flows occur in the well structure.

There are application limits with regard to the quality of the raw water. Demanganization in particular requires a minimum pH value, which is lower than with above-ground processes due to the high efficiency of the process.

In addition, the treatment effort increases significantly with higher ammonium or methane concentrations in the groundwater. There are no limits for iron or manganese concentrations in the raw water (contrary to various publications, see also[1]). With FERMANOX®, even extreme groundwater can be treated to drinking water level.

In order to assess the applicability of the process, offer a suitable water treatment plant and ensure the usual FERMANOX® guarantee (below the Drinking Water Ordinance limit values for iron, manganese and ammonium), we therefore require the following documents:

- Raw water analyses of all wells

- Layer and development lists of all wells (→ DIN 4023 and 4943)

- Site plan

- Information on pumping capacity and concept

- Records of well development (if available, e.g. records of de-sanding and power pumping tests)

Possibly hydrogeological reports If necessary, preliminary tests are useful, for which we can offer test systems.

[1] Groth, Peter ; Czekalla, Christian ; Dannöhl, Rainer ; Kölle, Walter ; Ließfeld, Rainer ; Meyerhoff, Ralf ; Olthoff, Reinhold ; Rott, Ulrich ; Wiegleb, Klaus: Unterirdische Enteisenung und Entmanganung – aktualisierter Statusbericht. In: gwf – Wasser/Abwasser (Sonderdruck) 138 (1997) Nr. 4, S. 182-187

The FERMANOX® water treatment process guarantees iron, manganese and ammonium-free water – directly from the well.

Advantages of FERMANOX® water treatment

Healthy, delicious water

No discoloration

Water treated with FERMANOX® is free of iron and manganese and therefore does not leave any brown or black discoloration when used. This keeps laundry, sinks, showers, bathtubs and tiles clean.

No deposits

Since underground treatment prevents iron and manganese deposits (calcification) on wells, pumps and pipes, cleaning or regeneration is no longer necessary.

The FERMANOX® system significantly extends the service life of your entire water supply system, as only pure, treated water flows through wells, pumps and pipes.

Submersible pumps after 5 years of operation with FERMANOX® (above) and a conventional gravel filter (below)

Maximum efficiency – minimum energy consumption

In contrast to conventional methods, the FERMANOX® system only requires a small amount of oxygen-rich water, which is fed into the aquifers for treatment, since the natural reaction zone in the area surrounding the well is many times larger than the filter volume of above-ground filters.

As a result, the energy requirement for the entire water supply is significantly lower than with conventional water treatment.

No maintenance – just checks!

Since the water treatment in the FERMANOX® process takes place in the aquifer itself, no regular maintenance is required, just an inspection.

In small FERMANOX® water treatment systems, the strainer in front of the system must be checked once a year to ensure that the oxygen enrichment performance does not drop due to blockages. Large systems are completely maintenance-free.

No filters, no backwash

In contrast to conventional methods, no above-ground filters are necessary. The water is naturally treated before it is pumped and used – without chemicals or replacement material.

Annoying and expensive replacement and disposal of filter material as well as backwashing of the filters are no longer necessary.

[1]Gesetzliche Grundlage ist die Trinkwasserverordnung in der Fassung der Bekanntmachung vom 28. November 2011 (BGBl. I S. 2370), die durch Artikel 2 Absatz 19 des Gesetzes vom 22. Dezember 2011 (BGBl. I S. 3044) geändert worden ist.

FERMANOX® water treatment for livestock farming | FERMANOX® system types

The requirements for a water treatment plant vary depending on the water demand, water quality and control requirements in the specific application. We have suitable FERMANOX® systems for every application, which can be divided into the following basic types:

| FERMANOX®-plant |

Water supply

|

Area of application | Control/regulation | Possibility of monitoring |

|---|---|---|---|---|

| Type BV | with 1 borehole | for smaller capacities; up to max. 15 m³/day | consumption-dependent | yes |

| Type BZ | with 1 borehole | for smaller capacities; up to max. 10 m³/day | time dependent | no |

| Type WV | with 2 production wells | for medium performance; 5 – 250 m³/day | consumption-dependent | yes |

Versions of the different basic types

Behind each of the FERMANOX® basic types listed above there are a variety of systems of different sizes and equipment (e.g. type BV 30 P).

The suitable system can only be selected after an individual design (depending on the water requirement and the water quality of the groundwater) by Winkelnkemper GmbH.

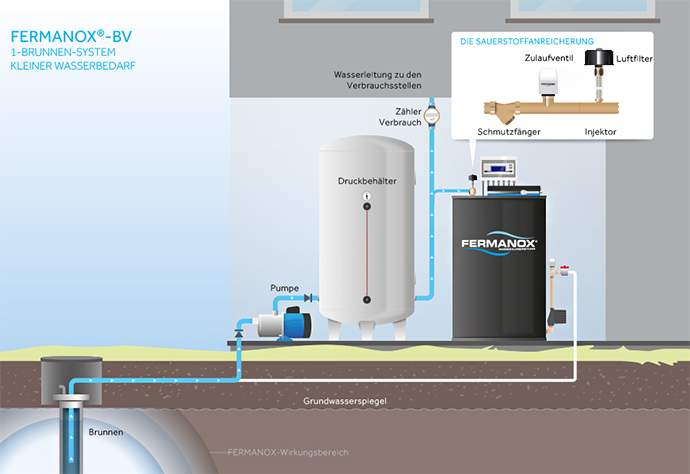

Installation example FERMANOX®-BV | 1-well system | Small water requirement

Installation example of water treatment plant FERMANOX WV (illustration)

Illustration FERMANOX®-BV | 1-well system | Small water requirement

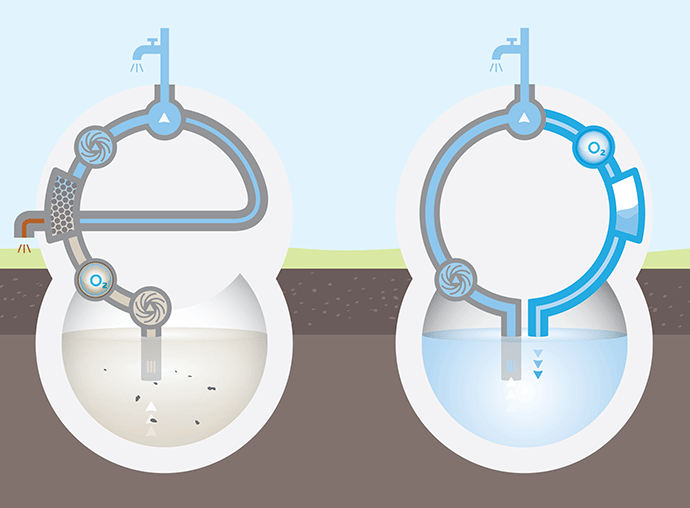

When choosing between above-ground and underground iron and manganese removal, it is worth comparing both alternatives based on efficiency and cost-effectiveness.

If you compare underground iron and manganese removal with an open gravel filter without additives (i.e. without hardening or addition of auxiliary materials, etc.), the following qualitative picture emerges:

- Concept comparison FERMANOX compared to the gravel filter process

Underground iron and manganese removal using the FERMANOX water treatment process is more efficient.

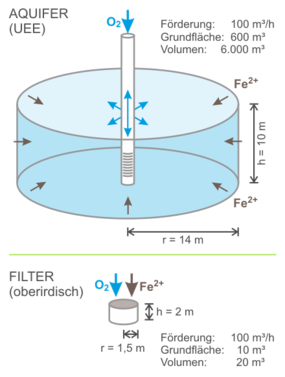

To understand the significantly higher efficiency of underground iron and manganese removal compared to above-ground rapid filters, a comparison of the reaction chambers is helpful.

With an effective pore volume of around 25% in a loose rock aquifer, infiltration creates a reaction chamber that has a volume of around 4 times the infiltration volume – many times larger than with conventional rapid filters. In this large chamber, the water is pumped to the well. Infiltration takes place in the opposite direction from the well into the aquifer. In contrast to conventional filters, the entire reaction chamber is thus active for the treatment, and the processes of oxidation and adsorption are largely separated, which is advantageous. Since the pumped volume always exceeds the infiltration volume, there is no change in the equilibrium prevailing in the aquifer beyond the reaction chamber.

Comparison of reaction space sizes in the aquifer and in the above-ground filter acc. [1]

The large reaction space or the huge surface area active for adsorption and reaction, a long reaction time and the more favourable countercurrent principle in this reaction space result in an efficiency that is practically unattainable with above-ground processes. As a result, UEE achieves significantly higher treatment performance with lower oxygen requirements (and lower energy consumption). Even groundwater with extremely high iron and manganese concentrations can be treated with FERMANOX® to a concentration well below the limits of the Drinking Water Ordinance.

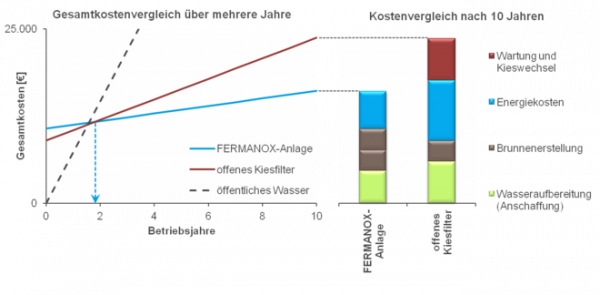

Underground water treatment offers high economic efficiency

Since the water supply with water treatment for stables is a long-term investment, it is important to consider not only the acquisition costs but also the ongoing operating costs when assessing the benefit of an investment.

Because in water treatment alone, choosing the right process over a period of several years will result in savings in operating costs that are greater than the investment costs of the entire system. The key to this lies in the energy and maintenance costs saved.

As the operating time increases, the operating costs become more important than the investment costs. In order to make the right decision between alternative systems, economic efficiency is a better basis than the purchase price.

This is illustrated by the following case studies, in which three alternatives are evaluated in terms of their economic efficiency:

- public water,

- own well water with open gravel filter,

- own well water with FERMANOX® system.

Case 1) Medium-sized farm (130 – 150 cows), water requirement approx. 20 m³/day

This shows that a water supply with FERMANOX® water treatment is the most economical alternative after just 2 years of operation.

With each additional year of use, the advantage (in favor of investing in FERMANOX® water treatment) becomes greater and greater due to the total cost savings (investment costs and running costs).

A second well is required for the FERMANOX® system, so the investment costs are initially higher. However, the lower energy and maintenance costs result in enormous savings compared to the gravel filter. After just 9 years of operation, FERMANOX® has achieved savings in this case study that are higher than the purchase costs for a gravel filter system!

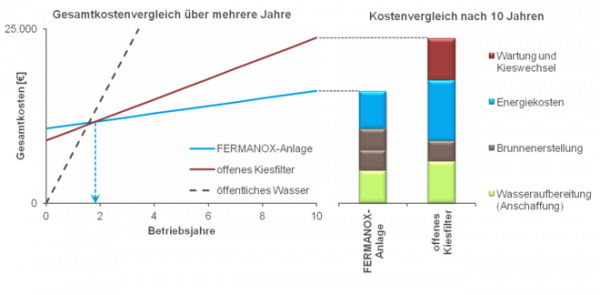

Case 2) Large farm (1,000 cows), water requirement approx. 150 m³/day

If you have a large water requirement, FERMANOX® is the cheapest concept right from the start.

Even the investment costs (water supply with FERMANOX® water treatment) are cheaper. In addition, you have significant savings in running costs compared to the alternative. And with each additional year of use, the advantage becomes greater and greater due to the amount of running costs saved.

Public water is ruled out from the start because of the high costs.

But even with an open gravel filter, the total costs after 10 years are around 70% higher than with a FERMANOX® system. After just 4 years, the cost difference is higher than the purchase price. This is mainly due to the different energy requirements.

Why is the energy consumption of a FERMANOX® system so low?

Gravel filter systems generally use significantly more electricity than FERMANOX® systems. With an open gravel filter, for example, all the water is pumped from the well to the filter system for spraying. A second pump then brings the water to the stable supply after filtration. The backwash water must also be pumped. This means that 2 to 2.5 m³ of water must be pumped so that 1 m³ of water can be used in the stable.

With the FERMANOX® process, depending on how well the water can be treated, an average of 25 – 30% of the process water is enriched with oxygen and returned via the wells. This means that only 1.3 m³ of water needs to be pumped so that 1 m³ of water, treated to drinking water quality, is available in the stable.

Result:

For a herd of 200 cows, for example, around 20,000 kWh of electricity can be saved over 10 years.

Other good reasons for FERMANOX® water treatment

The advantages are even more obvious than shown in the above figure if the following aspects are also taken into account:

- Additional energy requirement for backwashing with an open gravel filter. (This depends heavily on the raw water and the level of automation of the gravel filter system.)

- The generally significantly longer service life of the boreholes and pumps in the FERMANOX® system due to the avoidance of calcification Connection costs for public water

Reference projects

Type: WV 30/1/25 Nr.1860

Capacity: 45m³/day

In operation since 2011

Type: WV 50/3/31P Nr.1913

Capacity: 100m³/day

In operation since 2013

Types: WV 50/3/31P Nr.1911 and WV 40/2/25P Nr.1830

Capacity: 41 m³/day | 40 m³/day

In operation since 2013 | 2010