Groundwater for the irrigation of golf courses, sports fields, nurseries or parks with the water treatment of FERMANOX®

Whether it is a lawn, golf course or sports field, cultivated land, tree nursery or park – wherever irrigation is necessary, large quantities of good quality water are needed in a short space of time.

Private water supplies are often made from groundwater that is available locally and is extracted from deeper soil layers, the aquifers, via boreholes. Groundwater is recharged through rainwater and, to a small extent, from surface water. As the water seeps away, it absorbs minerals and trace elements that are very valuable for watering plants.

Having your own water is worth it

The sometimes very high water requirement for sufficient irrigation underlines the importance of having your own water supply. Private water supplies with high-quality groundwater result in significant cost savings. From an economic point of view, they are a must today.

Public water

The price of public water varies, but is mostly in the range of around €1.00/m³.

Private water

In contrast, with private water supplies it is quite possible to permanently reduce the price to around €0.08/m³ by selecting advantageous components for equally good water quality.

Problems of groundwater use as industrial water

Groundwater is formed from rainwater that seeps into the soil.

However, the water also becomes increasingly poor in oxygen. Due to the lack of oxygen, iron (Fe2+) and manganese (Mn2+) dissolve in increased concentrations.

However, water with high iron or manganese contents requires treatment before it can be used as process water or industrial water, otherwise it causes discoloration and ochre deposits.

Well aging

Various processes between chemical and biological components of the groundwater and the soil lead to well aging in the course of operation. This refers to the reduction in well performance, primarily due to the deposition of reaction products in the well or in the soil layers near the well.

As soon as the water inlet areas into the well are reduced, the pumping capacity decreases or the lowering of the operating water level increases while the withdrawal volume remains the same.

The main causes are:

- chemical and biological calcification

- sintering

- sliming

- silting

While silting can result from errors in well construction, the other causes depend primarily on the quality of the raw water and the operation of the well.

Clogging

Caustic deposits (iron or manganese-containing deposits) occur wherever iron (Fe2+) or manganese ions (Mn2+) dissolved in groundwater come into contact with oxygen and are oxidized. Since the oxidation of iron and manganese requires different redox potentials, either rust-brown iron caustic deposits or black manganese caustic deposits occur, but rarely both. Where both species are present in the groundwater, initially only the iron is oxidized.

Caustic deposits cause problems in boreholes, pumps, pipelines and sprinklers and require regular, complex cleaning, regeneration, repair or replacement. This not only leads to high costs, but also endangers the operational reliability of the irrigation system.

The most efficient method of preventing caustic deposits is the use of underground iron and manganese removal. This efficiently removes iron and manganese from the water before it enters the well.

Discoloration caused by water containing iron

Water containing iron leaves brown discoloration on all surfaces that come into contact with it. The brown discoloration is particularly annoying on paths and stone slabs or on house walls near irrigated areas.

But discoloration can also remain on plant leaves, which can reduce the value of the plant when sold commercially, for example.

Sealing of the surface by deposits

Areas that are frequently irrigated with water that contains a lot of iron can become so sealed by iron-containing deposits that they absorb water less well. All of these problems can be avoided by removing iron and manganese with FERMANOX®.

The solution for process water treatment: Underground iron and manganese removal (UEE)

The underground iron and manganese removal of groundwater (process water treatment) (UEE) with FERMANOX® activates a natural treatment process in the aquifer before extraction. With little effort, iron and manganese concentrations at drinking water level can be generated there. This effectively prevents all discoloration and ochre formation. At the same time, the process is particularly sustainable because

- no filter material is required,

- no waste water or waste is produced,

- energy requirements are particularly low and

- the service life of the boreholes is increased.

The process: Underground iron and manganese removal with FERMANOX

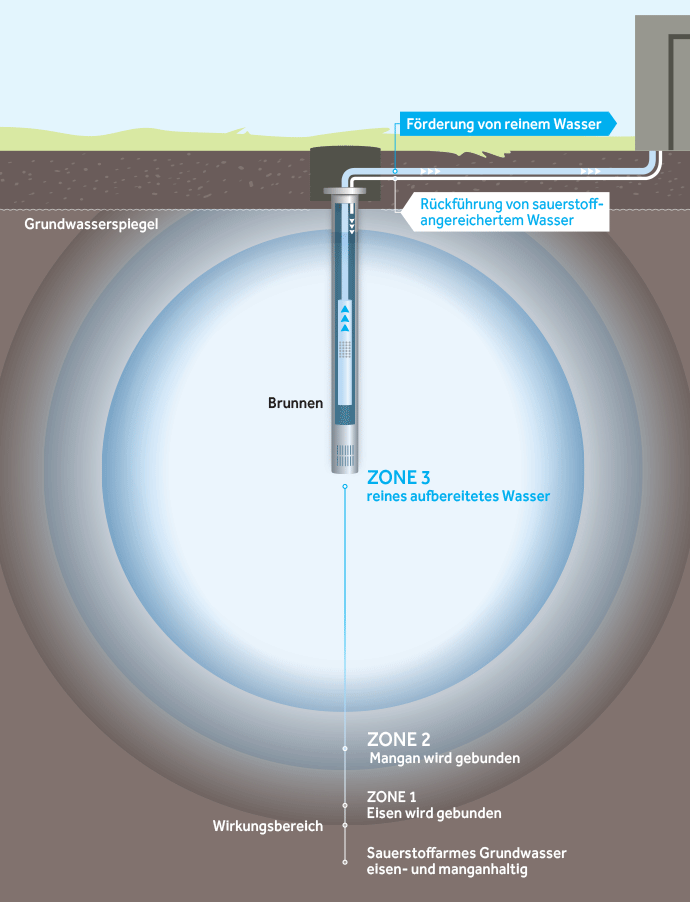

Oxidation zones in the aquifer when using an UWE

The basic idea behind underground deferrification and demanganization is the introduction of water enriched with atmospheric oxygen into the aquifer. Even small amounts of oxygen activate an effective water treatment process there, because a reaction space with an increased redox potential is created around the well.

The substances that were dissolved in the aquifer due to reduced conditions are returned to the solid state by oxidation and are then permanently fixed again in the same aquifer at another location. This achieves efficient deferrification and demanganization of the groundwater and also nitrification of ammonium, a reduction in easily oxidizable organic substances and a reduction in arsenic.

Continuous underground water treatment is based on the operation of at least two wells that work alternately as extraction or infiltration wells. The size of the reaction space around each well is determined by the amount of infiltration and the proportion of active pore volume in the aquifer. It requires an individual design for each well, which is based primarily on the raw water quality and the required treatment capacity.

History

The underground iron and manganese removal of groundwater has been used on a large scale since the 1970s, and since the 1980s in a variety of small and medium-sized plants for drinking and industrial water treatment, primarily in Germany, the Netherlands and Scandinavia, in various designs. Winkelnkemper GmbH has been manufacturing FERMANOX® water treatment systems since 1984 and is now the market leader in the field of underground iron and manganese removal, with over 10,000 compact systems installed.

The FERMANOX® water treatment process guarantees iron, manganese and ammonium-free water – directly from the well.

FERMANOX® water treatment systems | Process water treatment

The requirements for a water treatment plant for industrial water vary depending on the water requirement, water quality and control requirements in the specific application. Depending on the size of the company and the quality of the raw water, the following FERMANOX® water treatment plant types are available:

| FERMANOX®-type | Water supply | Area of application | Control/regulation | Possibility of monitoring |

|---|---|---|---|---|

| Type BV | with 1 abstraction well |

for small capacities; up to 15 m³/day |

consumption-dependent | yes |

| Type WV | with 2 abstraction wells |

for medium capacities; 5 – 250 m³/day |

consumption-dependent | yes |

| Type WV professional |

with 2 abstraction wells | for large capacities; 100 – 8,000 m³/day | consumption-dependent | yes |

Versions of the different basic types

Behind each of the FERMANOX® basic types listed above there are a variety of systems of different sizes and equipment (e.g. type WV 50/3/28 P). The suitable system can only be selected after an individual design (depending on the water requirement and the water quality of the groundwater) by Winkelnkemper GmbH.

FERMANOX® system type WV

The basic requirement for the use of FERMANOX® systems for underground iron and manganese removal is vertical or horizontal filter wells in loose rock (sand or gravel), because the actual processing requires the large surface area of a porous aquifer. The usual technical rules apply to the well construction (especially DVGW W 113, W 123 and DIN 4924). In addition, it is particularly important to ensure that no vertical flows occur in the well structure.

There are application limits with regard to the quality of the raw water. Demanganization in particular requires a minimum pH value, which is lower than with above-ground processes due to the high efficiency of the process. In addition, the treatment effort increases significantly with higher ammonium or methane concentrations in the groundwater. There are no limits for iron or manganese concentrations in the raw water (contrary to various publications, see also [1]). With FERMANOX®, even extreme groundwater can be treated to drinking water level.

In order to assess the applicability of the process, offer a suitable water treatment plant and ensure the usual FERMANOX® guarantee (below the Drinking Water Ordinance limit values for iron, manganese and ammonium), we therefore require the following documents:

- Raw water analyses of all wells

- Layer and development lists of all wells (→ DIN 4023 and 4943)

- Site plan

- Information on pumping capacity and concept

- Records of well development (if available, e.g. records of de-sanding and power pumping tests)

Possibly hydrogeological reports If necessary, preliminary tests are useful, for which we can offer test systems.

[1] Groth, Peter ; Czekalla, Christian ; Dannöhl, Rainer ; Kölle, Walter ; Ließfeld, Rainer ; Meyerhoff, Ralf ; Olthoff, Reinhold ; Rott, Ulrich ; Wiegleb, Klaus: Unterirdische Enteisenung und Entmanganung – updated status report. In: gwf – Wasser/Abwasser (Sonderdruck) 138 (1997) No. 4, page 182-187

Advantages of FERMANOX® water treatment

Healthy, delicious water

This is important because since 2011 there have been no exceptions for small suppliers in the case of (geogenically caused) increased concentrations.

No discoloration

Water treated with FERMANOX® is free of iron and manganese and therefore does not leave any brown or black discoloration when used. This keeps laundry, sinks, showers, bathtubs and tiles clean.

No deposits

Since underground treatment prevents iron and manganese deposits (calcification) on wells, pumps and pipes, cleaning or regeneration is no longer necessary.

The FERMANOX® system significantly extends the service life of your entire water supply system, as only pure, treated water flows through wells, pumps and pipes.

Submersible pumps after 5 years of operation with FERMANOX® (above) and a conventional gravel filter (below)

Maximum efficiency – minimum energy consumption

In contrast to conventional methods, the FERMANOX® system only requires a small amount of oxygen-rich water, which is fed into the aquifers for treatment, since the natural reaction zone in the area surrounding the well is many times larger than the filter volume of above-ground filters.

As a result, the energy requirement for the entire water supply is significantly lower than with conventional water treatment.

No maintenance – just checks!

Since the water treatment in the FERMANOX® process takes place in the aquifer itself, no regular maintenance is required, just an inspection.

In small FERMANOX® water treatment systems, the strainer in front of the system must be checked once a year to ensure that the oxygen enrichment performance does not drop due to blockages. Large systems are completely maintenance-free.

No filters, no backwash

In contrast to conventional methods, no above-ground filters are necessary. The water is naturally treated before it is pumped and used – without chemicals or replacement material.

Annoying and expensive replacement and disposal of filter material as well as backwashing of the filters are no longer necessary.

[1] The legal basis is the Drinking Water Ordinance in the version published on 28 November 2011 (BGBl. I page 2370), which was amended by Article 2 paragraph 19 of the Act of 22 December 2011 (BGBl. I p. 3044).

Iron and manganese in groundwater? One problem – two solutions

Since iron and manganese cannot be filtered out in dissolved form, the water must be enriched with atmospheric oxygen for water treatment so that solids are formed again, which are then separated.

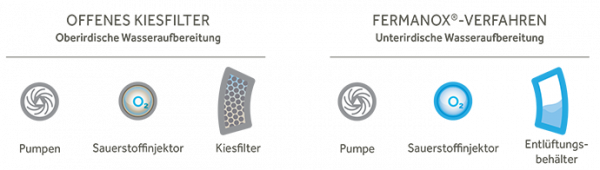

Concept comparison FERMANOX compared to the gravel filter process

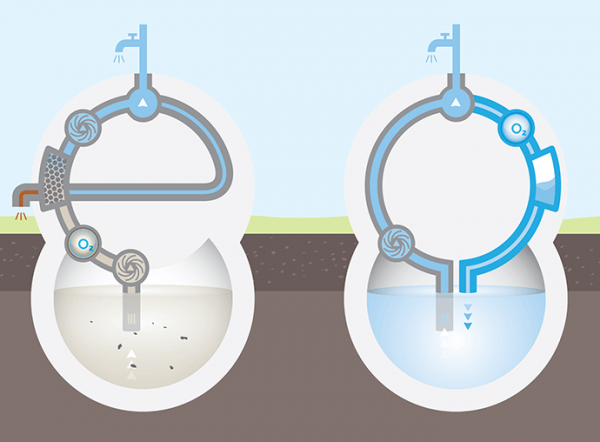

Above-ground water treatment

In traditional water treatment systems – mostly gravel filter systems – the groundwater is only treated above ground after extraction by enriching it with oxygen from the air. This causes the dissolved metals to oxidize into solid particles, which can then be separated – usually using sand or gravel filters.

Since these systems can only absorb limited amounts of iron and manganese deposits, the filters must be backwashed regularly to remove the separated metal oxides and to restore the filter’s cleaning power. In extreme cases, high iron and manganese contents even require daily backwashing. The iron and manganese sludge that is washed out usually has to be disposed of.

In addition, the filter gravel – even if the filter systems are backwashed regularly – becomes unusable after years and has to be replaced and disposed of. Since all the service water and additional backwash water has to be pumped through the above-ground gravel filter, multiple pumping results in a high energy requirement.

FERMANOX® process

FERMANOX® water treatment takes place directly in the groundwater-bearing soil layers. Therefore, only treated water is pumped and can be used immediately. This prevents calcification of wells, pumps and pipes from the very beginning. FERMANOX® water treatment is maintenance-free and has no follow-up costs.

The German Association of the Gas and Water Industry (DVGW) confirms the low operating costs of the process in its technical rule W 223 on FERMANOX® water treatment and explains “Even in systems that have been in operation for many years, neither blockage of the groundwater with reaction products nor a reduction in treatment performance has been observed.”

Concept comparison

Concept comparison FERMANOX® compared to the gravel filter process

The FERMANOX® water treatment process is probably the most efficient on the market

To understand why a FERMANOX® water treatment system is much more efficient than a gravel filter, a comparison of the size of the treatment zones helps. In a gravel filter, this treatment zone is the gravel fill, and its size is determined by the container that is set up and through which the water flows.

In FERMANOX®, sand and gravel in the aquifer form the treatment zone, and its size is determined by the amount of oxygen-containing water that is returned via the borehole. This treatment zone is many times larger than in gravel filter systems. In addition, the residence time of the water in the treatment zone and thus the contact time between iron or manganese and oxygen is significantly longer in the FERMANOX® system (in the same ratio) than in a gravel filter.

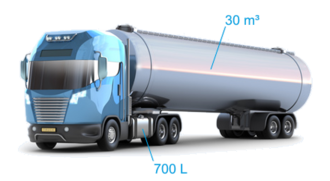

A size comparison

For example, if you assume a water requirement of 30 m³ per day, a gravel filter with around 700 litres of gravel could be used for medium raw water quality. Under the same conditions, the treatment zone of a FERMANOX® system in the ground would have a volume of around 30 m³, i.e. more than 40 times the size. In a tanker truck, this corresponds to the size ratio between the tank trailer and the fuel tank.

A size comparison of water treatment systems

Countercurrent principle

In addition, in a gravel filter, the iron-containing water flows through the filter from top to bottom after oxygen enrichment, and the iron removal takes place almost exclusively in the upper layers. With FERMANOX®, oxygen-containing water (during the return phase) and iron-containing water (during the conveying phase) flow in opposite directions. This countercurrent principle creates very favorable treatment conditions. A significantly larger part of the treatment zone is therefore active for the iron removal.

Conclusion

All of this results in FERMANOX® water treatment achieving better water quality with significantly less energy than a gravel filter and is the reason for FERMANOX®’s technological advantage.

Reference projects

Type: WV 50/3/25 P

Capacity: 20,5 m³/day

In operation since 2003

Type: WV 80/1/40 P

Capacity: 450m³/day

In operation since 2020