Water – the most important feed for horses

Water is the most important feed for horses.[1] All body cells need water to perform their tasks. It is needed for all metabolic steps, to maintain fluid in the blood, for thermoregulation and, in mares, for milk production. Without water, the transport of nutrients and oxygen comes to a standstill.[2]

Water makes up about 70% of a horse’s body weight. Even a water loss of 3% of its body weight already limits the horse’s performance. Signs of illness appear with a fluid loss of just 8%.[2]

Horses need about 20 – 60 liters of water per day – depending on size, weight, age, breed, feed, weather and use.[3] For every kilogram of dry or roughage, a horse’s water requirement increases by about 3 – 4 liters.[2]

Groundwater for horses – naturally healthy

Horses should have constant access to fresh, clean water so that an adequate water supply is guaranteed at all times.[4] Groundwater or well water is ideal for supplying horses with water, as it is usually available close to the farm and is naturally healthy. As the water slowly seeps through the soil layers, many undesirable substances are naturally purified.

As it seeps through the upper soil layers, the water is both filtered and changed in many ways by dissolving and microbiological processes. At the same time, the water absorbs valuable minerals and trace elements that improve the quality of the water in terms of health aspects.

Having your own water is worth it

Public water

The price for public water varies, but is mostly in the range of around €1.00/m³.

Private water

In contrast, with your own water supply, by selecting the optimal water treatment plant, it is entirely possible to achieve both the same drinking water quality and a permanent price reduction to approx. 0.08 €/m³ – and thus high water quality at a good price.

[2]www.tierarzt-owschlag.de/pdf/Pferd%201-2008.pdf , Tiergesundheit aktuell, Heike Flenner, S. 12, Wasser ist Lebenselexier: Wie viel Wasser in welcher Qualität brauchen Pferde, 22.05.2013

[3]equivetinfo.de/html/eckdaten_pferd.html , Dr. C. A. Bingold, Pferdeklinik Großostheim, 23.05.2013

[4]http://masterhorse-infowissen-de.prossl.de/index.php/w/wasserbedarf.html , , Status v. 07.05.2012 (abgerufen am 28.05.2013).

Difficulties caused by groundwater use

Groundwater is formed from rainwater that seeps into the soil. As it seeps through the soil layers, the water is microbiologically purified, but at the same time it becomes increasingly oxygen-poor. In the deep groundwater-bearing soil layers, the groundwater usually no longer contains any oxygen.

Due to the lack of oxygen, iron (Fe2+) and manganese (Mn2+) dissolve in increased concentrations. Ammonium (NH4+) can also be formed during biological decomposition processes under a lack of oxygen. In dissolved form, these substances cannot be filtered out.

On the one hand, iron and manganese are trace elements that horses need, but which are excreted if they are consumed in too high quantities. However, the need is usually more than covered by the feed.

On the other hand, increased iron and manganese levels lead to significant problems in animal husbandry. In addition, water containing iron and manganese causes brown or black deposits and discoloration.

Tasty water for horses

Water quality is crucial for the taste of the water.[1] As the iron content increases, the taste deteriorates, leading to lower water intake by horses and, as a result, lower feed intake.

Chemical water quality

Soaking water quality

Drinking water quality

Iron and manganese deposits (ochre deposits)

Iron and manganese also cause significant problems in the water supply systems themselves due to the ochre formation in wells and pumps and deposits in pipes and drinking troughs.[4]

Eliminating the effects of iron in the system is usually associated with considerable time and expense. The ochre formation in wells often leads to a significant reduction in their performance and service life or the need for regeneration or reconstruction.

When the FERMANOX® process is used, ochre formation in the entire water supply is effectively prevented from the outset. When FERMANOX® systems are used, no water containing iron and manganese flows through wells, pumps and water pipes, as the water is treated before it is pumped.

Iron deposits – calcified impeller in a submersible pump

[1] www.tierarzt-owschlag.de/pdf/Pferd%201-2008.pdf , Tiergesundheit aktuell, Heike Flenner, S. 12, Wasser ist Lebenselexier: Wie viel Wasser in welcher Qualität brauchen Pferde, 22.05.2013

[2] www.landwirtschaftskammer.de/lufa/download/fachinfo/wasser/beurteilungswerte-traenkwasser.pdf ; Beurteilungswerte für Tränkwasser, Landwirtschaftskammer Münster

[3] http://www.landwirtschaftskammer.de/landwirtschaft/tierproduktion/pferdehaltung/fuetterung/futterrationen-berechnen.htm , Landwirtschaftskammer Nordrhein-Westfalen, Dr. Wolfgang Sommer, Fassung v. 18.03.2004, 23.05.2013

[4] http://www.lksh.de/fileadmin/user_upload/Presse/Archiv_2011/BB_4211_22.10.2011/42-44_Fuebbeker.pdf ; Alfons Fübecker, Landwirtschaftskammer Niedersachsen, Wasserenteisenung dringend notwendig, 22.10.2011

The solution: FERMANOX® water treatment of groundwater for horses

Since groundwater with a low oxygen content dissolves iron and manganese from the soil, oxygen must be added to the water in order to immobilize the metals again and thus remove them from the water.

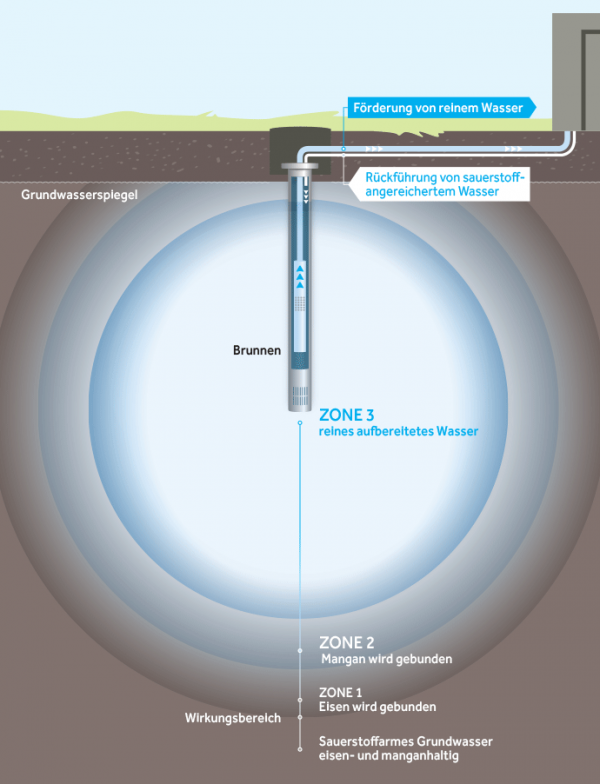

In the FERMANOX® process (underground iron removal and demanganization), part of the extracted water is enriched with atmospheric oxygen and returned directly to the groundwater-bearing soil layers (aquifer) via the borehole. There, the oxygen introduced creates a treatment zone in which the dissolved metals iron and manganese react to form high-strength crystals and are thus separated from the groundwater. This treatment takes place as soon as iron and manganese in the incoming water come into contact with the oxygen in the treatment zone.

The formation of the crystalline oxides therefore occurs at the outer edge of the treatment zone. At the same time, the oxygen introduced also converts ammonium and nitrite and thus removes them from the groundwater. A zone of pure water that is free of iron and manganese forms around the borehole. After this natural treatment in the aquifer, a much higher volume of water of drinking quality can be extracted from the well.

Principle of operation / functionality of the FERMANOX® process

Requirements for the borehole

The basic requirement for using the FERMANOX® process is the presence of one or more boreholes in the loose rock (sand or gravel), because the actual processing takes place in the pores of the aquifer. The boreholes themselves must be created in accordance with the usual technical rules and (if there are several wells) with sufficient spacing and with the shortest possible filter sections. If there are several boreholes, the spacing must be agreed with us.

Raw water quality

There are no application limits for iron or manganese concentrations in the raw water. FERMANOX® is even able to treat extreme groundwater to drinking water level, where the raw water values are many times higher than the limit values of the Drinking Water Ordinance. Demanganization in particular requires a minimum pH value of the raw water, which is lower than with above-ground processes due to the high efficiency of the process – without the addition of chemicals. With higher ammonium or methane concentrations in the groundwater, the treatment effort increases significantly.

FERMANOX® -Design

The correct design of the FERMANOX® system is of crucial importance for the long-term optimal operation of the system. In order to check the requirements and offer a suitable water treatment system, we require the following documents:

- Information on water requirements

- Water analyses of existing wells

- Data on well construction

We will be happy to carry out the necessary water analyses for you using raw water samples.

FERMANOX® – Guaranteed drinking water quality

The first Fermanox® plant was put into operation in 1983. The iron content of the original raw water was 6.7 mg/l, which is 33.5 times the limit value according to the Drinking Water Ordinance. The plant has been running smoothly to this day, even though the borehole is now around 60 years old.

Many thousands of installed systems, references in the treatment of groundwater with extreme iron and manganese levels as well as reports from satisfied customers prove our competence as a specialist in underground water treatment.

FERMANOX®– Guarantee

FERMANOX® guarantees drinking water quality (according to the valid Drinking Water Ordinance 2001[1]) with regard to iron, manganese and ammonium.

| Parameter | Limit |

|---|---|

| Ammonium: | 0,5 mg/l |

| Iron: | 0,2 mg/l |

| Manganese: | 0,05 mg/l |

In addition, FERMANOX® also guarantees compliance with or below the limit values according to the Drinking Water Ordinance with regard to other oxidizable ingredients that occur less frequently, such as nitrite, arsenic, hydrogen sulphide and methane.

[1]Gesetzliche Grundlage ist die Trinkwasserverordnung in der Fassung der Bekanntmachung vom 28. November 2011 (BGBl. I S. 2370), die durch Artikel 2 Absatz 19 des Gesetzes vom 22. Dezember 2011 (BGBl. I S. 3044) geändert worden ist (zukünftig verwendet als Abkürzung: TrinkwV 2001)

Tasty and healthy – simply drinking water

Water is the most important feed for horses.

Effective protection against deposits (ochre deposits)

Many thousands of installed systems, references in the treatment of groundwater with extreme iron and manganese levels as well as reports from satisfied customers prove our competence as a specialist in underground water treatment.

Submersible pumps after 5 years of operation with FERMANOX® (above) or with a gravel filter (below)

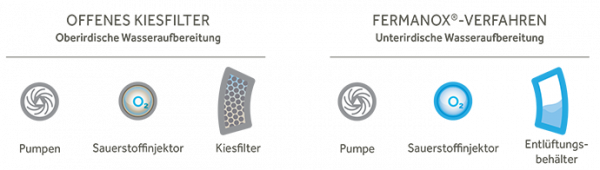

No filters, no backwash

In contrast to conventional methods, no above-ground filters are necessary. The water is naturally treated before it is pumped and used.

Annoying and expensive replacement and disposal of filter material as well as backwashing of the filters are no longer necessary.

No regular maintenance required – just checking

Since the actual water treatment in the FERMANOX® process takes place in the aquifer itself, no regular maintenance is required, just a check.

In small FERMANOX® water treatment systems, the strainer in front of the system must be checked once a year to ensure that the oxygen enrichment performance does not drop due to blockages. Large systems are completely maintenance-free.

Conclusion

FERMANOX® water treatment is the recommendable and advantageous investment in the concept comparison, as the FERMANOX® process is both more efficient and more economical than the open gravel filter due to its technological advantage.

[1]Gesetzliche Grundlage ist die Trinkwasserverordnung in der Fassung der Bekanntmachung vom 28. November 2011 (BGBl. I S. 2370), die durch Artikel 2 Absatz 19 des Gesetzes vom 22. Dezember 2011 (BGBl. I S. 3044) geändert worden ist (zukünftig verwendet als Abkürzung: TrinkwV 2001)

FERMANOX®-Water treatment systems for horse husbandry | Riding stables FERMANOX® system types:

The requirements for a water treatment plant for industrial water vary depending on the water requirement, water quality and control requirements in the specific application. Depending on the size of the company and the quality of the raw water, the following FERMANOX® water treatment plant types are available:

| FERMANOX®-Type | Water supply | Area of application | Control/regulation | Possibility of monitoring |

|---|---|---|---|---|

| Type BV | with 1 abstraction well |

for small capacities; up to 15 m³/day |

consumption-dependent | yes |

| Type WV | with 2 abstraction wells | for medium capacities; 5 – 250 m³/day | consumption-dependent | yes |

Versions of the different basic types

Behind each of the FERMANOX® basic types listed above there are a variety of systems of different sizes and equipment (e.g. type BV 30 P).

The suitable system can only be selected by Winkelnkemper GmbH after an individual design (depending on the water requirement and the water quality of the groundwater).

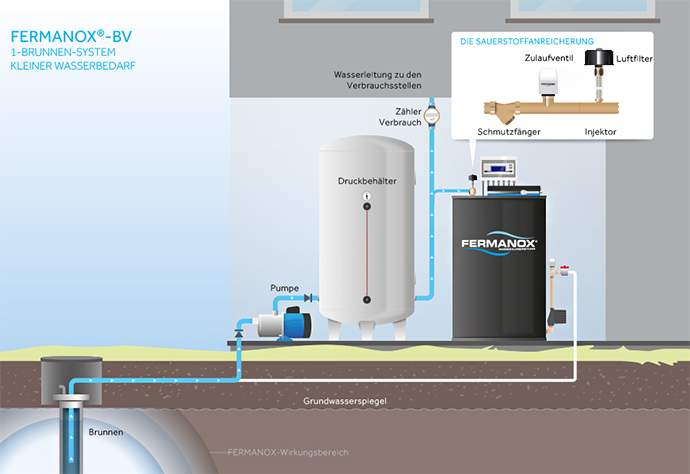

Installation example FERMANOX®-BV | 1-well system | Small water requirement

Installation example water treatment plant FERMANOX BV (illustration)

Illustration FERMANOX®-BV | 1-well system | Small water requirement

Iron and manganese in groundwater? One problem – two solutions

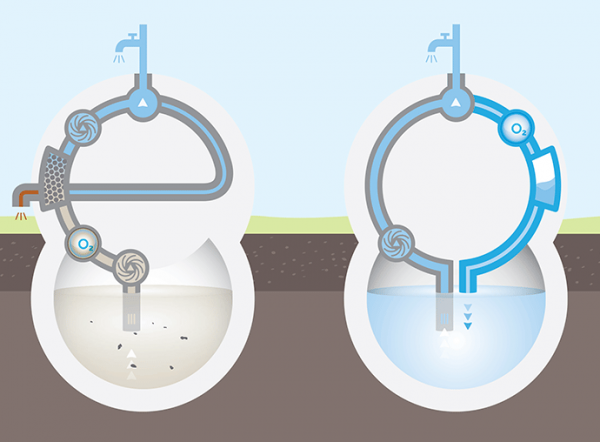

Since iron and manganese cannot be filtered out in dissolved form, the water must be enriched with atmospheric oxygen for water treatment so that solids are formed again, which are then separated.

Concept comparison FERMANOX compared to the gravel filter process

Above-ground water treatment

In traditional water treatment systems – mostly gravel filter systems – the groundwater is only treated above ground after extraction by enriching it with oxygen from the air. This causes the dissolved metals to oxidize into solid particles, which can then be separated – usually using sand or gravel filters.

Since these systems can only absorb limited amounts of iron and manganese deposits, the filters must be backwashed regularly to remove the separated metal oxides and to restore the filter’s cleaning power. In extreme cases, high iron and manganese contents even require daily backwashing. The iron and manganese sludge that is washed out usually has to be disposed of.

In addition, the filter gravel – even if the filter systems are backwashed regularly – becomes unusable after years and has to be replaced and disposed of. Since all the service water and additional backwash water has to be pumped through the above-ground gravel filter, multiple pumping results in a high energy requirement.

FERMANOX®-process

FERMANOX® water treatment takes place directly in the groundwater-bearing soil layers. Therefore, only treated water is pumped and can be used immediately.

This prevents calcification of wells, pumps and pipes right from the start. FERMANOX® water treatment is maintenance-free and has no follow-up costs (see FERMANOX® advantages).

Concept comparison

Concept comparison FERMANOX® compared to the gravel filter process

Why is a FERMANOX® system so efficient?

To understand why a FERMANOX® water treatment system is much more efficient than a gravel filter, a comparison of the size of the treatment zones helps. In a gravel filter, this treatment zone is the gravel fill, and its size is determined by the container that is set up and through which the water flows.

In FERMANOX®, sand and gravel in the aquifer form the treatment zone, and its size is determined by the amount of oxygen-containing water that is returned via the borehole. This treatment zone is many times larger than in gravel filter systems. In addition, the residence time of the water in the treatment zone and thus the contact time between iron or manganese and oxygen is significantly longer in the FERMANOX® system (in the same ratio) than in a gravel filter.

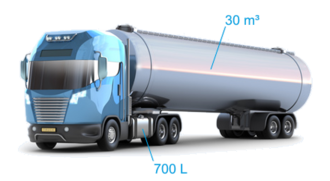

A size comparison

For example, if you assume a water requirement of 30 m³ per day, a gravel filter with around 700 litres of gravel could be used for medium raw water quality. Under the same conditions, the treatment zone of a FERMANOX® system in the ground would have a volume of around 30 m³, i.e. more than 40 times the size. In a tanker truck, this corresponds to the size ratio between the tank trailer and the fuel tank.

A size comparison of water treatment systems

Countercurrent principle

In addition, in a gravel filter, the iron-containing water flows through the filter from top to bottom after oxygen enrichment, and the iron removal takes place almost exclusively in the upper layers. With FERMANOX®, oxygen-containing water (during the return phase) and iron-containing water (during the conveying phase) flow in opposite directions. This countercurrent principle creates very favorable treatment conditions. A significantly larger part of the treatment zone is therefore active for the iron removal.

Conclusion

All of this results in FERMANOX® water treatment achieving better water quality with significantly less energy than a gravel filter and is the reason for FERMANOX®‘s technological advantage.

Which alternative is the most economical for your riding facility? – FERMANOX water treatment!

Since the water supply with water treatment for equestrian facilities and riding schools is a long-term investment, it is important to consider not only the initial costs but also the ongoing operating costs when assessing the benefit of an investment.

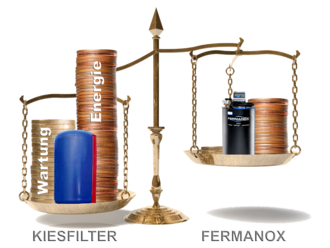

Because in water treatment alone, choosing the right process over a period of several years will result in savings in operating costs that are greater than the investment costs of the entire facility. The key to this lies in the energy and maintenance costs saved.

As the operating time increases, the operating costs become more important than the investment costs.

In order to make the right decision between alternative systems, economic efficiency is a better basis than the purchase price.

This is illustrated by the following case studies, in which three alternatives are evaluated in terms of their economic efficiency:

- public water,

- own well water with open gravel filter,

- own well water with FERMANOX® system.

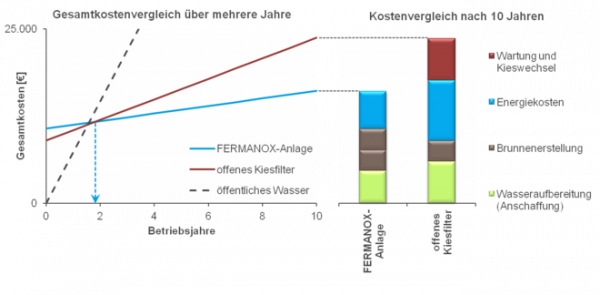

Case study: Riding stable or riding facility with high water requirements (approx. 20 m³/day)

Economic efficiency comparison of a riding stable or riding school with high water requirements (20 m³ water requirement per day)

This shows that a water supply with FERMANOX® water treatment is the most economical alternative after just 2 years of operation.

With each additional year of use, the advantage (in favor of investing in FERMANOX® water treatment) becomes greater and greater due to the total cost savings (investment costs and running costs).

A second well is required for the FERMANOX® system, so the investment costs are initially higher. However, the lower energy and maintenance costs result in enormous savings compared to the gravel filter. After just 9 years of operation, in this case study, FERMANOX® has achieved savings that are higher than the purchase costs for a gravel filter system!

Why is the energy consumption of a FERMANOX® system so low?

Gravel filter systems generally have a significantly higher power consumption than FERMANOX® systems. With an open gravel filter, for example, all the water is pumped from the well to the filter system for spraying with a first pump. A second pump then brings the water to the stable supply after filtration. In addition, the backwash water must also be pumped. This means that 2 to 2.5 m³ of water must be pumped so that 1 m³ of water can be used in the stable.

With the FERMANOX® process, depending on how well the water can be treated, an average of 25 – 30% of the amount of service water is enriched with oxygen and returned via the wells. This means that only 1.3 m³ of water needs to be pumped so that 1 m³ of water treated to drinking water quality is available in the stable.

Result: With a herd of 200 cows, for example, around 20,000 kWh of electricity can be saved within 10 years.

Other good reasons for FERMANOX® water treatment

The advantages are even more obvious than shown in the above figure if the following aspects are also taken into account:

- Additional energy requirement for backwashing with an open gravel filter. (This depends heavily on the raw water and the level of automation of the gravel filter system.)

- The generally significantly longer service life of the boreholes and pumps in the FERMANOX® system due to the avoidance of calcification

- Connection costs for public water